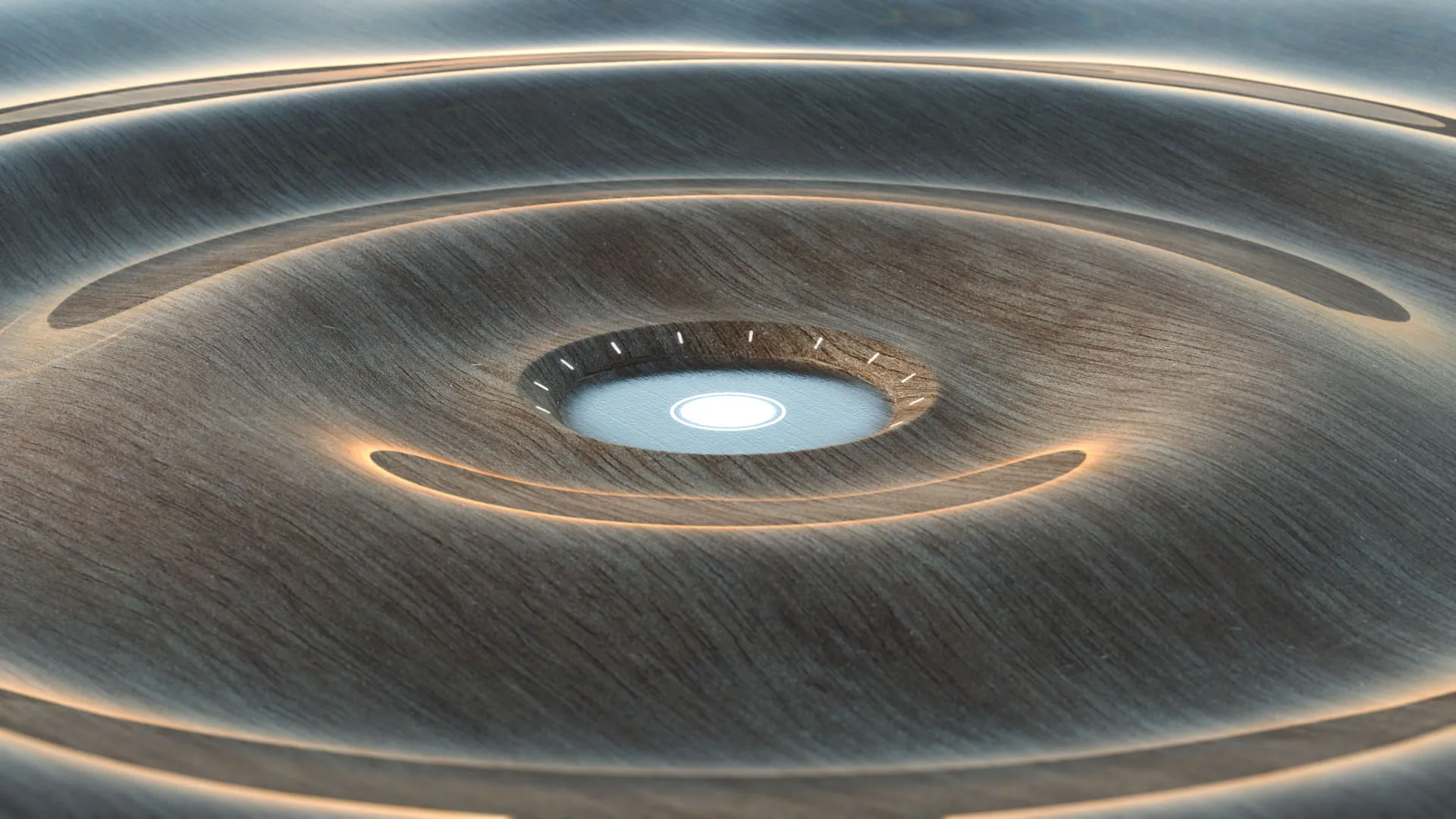

Let's turn conventional structures into smart, natural, and interactive surfaces.

We offer a smarter, more efficient, and sustainable way to develop unique user experiences with smart molded structures.

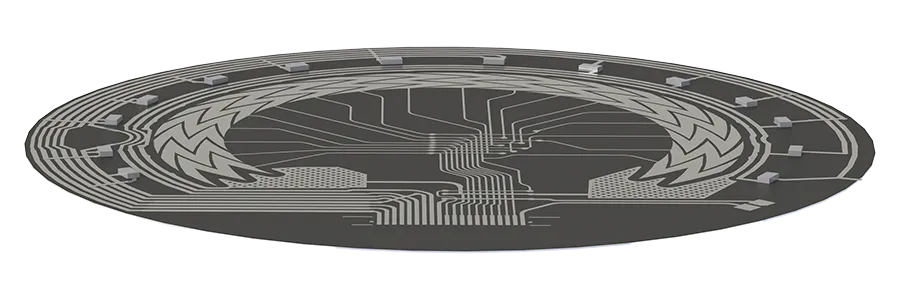

The decoration of your choice is printed on a film insert molding (FIM) material, followed by printing electronics including conductive circuitry, touch electrodes, antennas, and proximity sensors.

Electronic components are mounted on a flat plastic film using standard high-speed pick-and-place (SMT) equipment. Components are attached to the FIM substrate using conductive and structural adhesives.

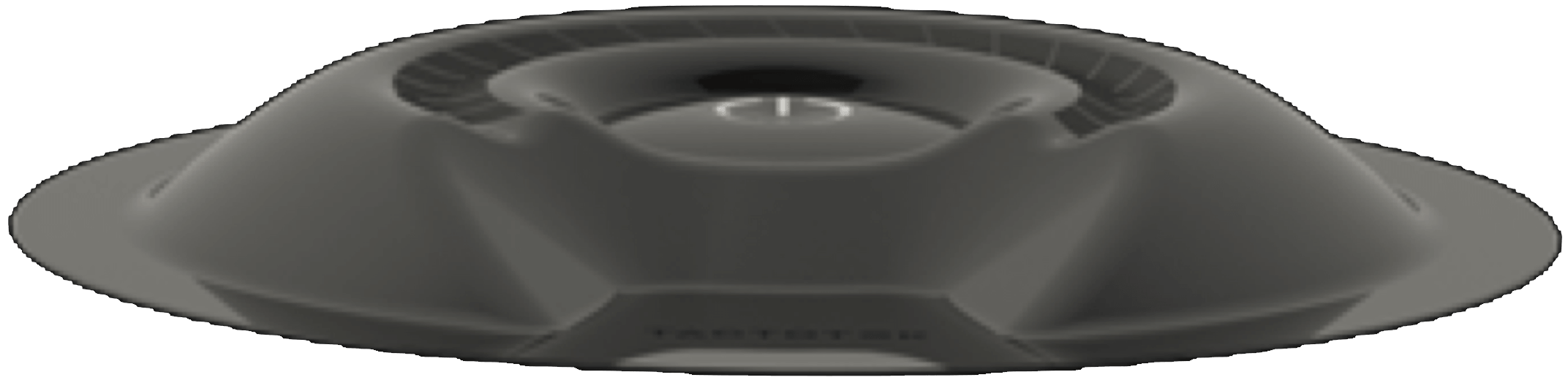

Thermoforming transforms the flat electronics film into its desired 3D shape.

The formed electronics film and cosmetic film are used as an insert for injection molding, resulting in a solid, single-piece structure with electronics encapsulated by injection molded plastics.